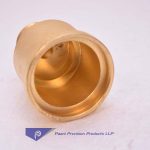

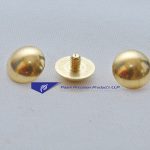

PRECISION BRASS COMPONENTS

We have shown rapid growth in the market and we provide our customers premium quality of Brass Component. We make the components with accuracy of as low as 10 microns.

High Quality Customized Turned Parts with great precision & Accuracy can be made very effectively by our CNC Machines in Metals like Brass, Stainless steel & Mild Steel and Aluminum.

Salient Features

⊗ Very High Quality Parts can be made of Turning diameter between 10mm to 70mm

⊗ High Processing accuracy to achieve Zero defect products leading to 0 PPM

⊗ Complex parts can be made effectively

⊗ Small batch quantity products can be undertaken which is of benefits to customers whose requirements are small or change at short notice

⊗ Any Kind of special turned parts can be made as per customer’s specifications.

- For connecting pipes or fittings of different types

- Brass for corrosion resistance, ductility at high temperatures, and low magnetic permeability

- Operating temperatures range from -53 to 121 degrees C (-65 to 250 degrees F)

- Meets specifications ASTM B584 and ASME/ANSI B16 for quality assurance

⇒ Free Cutting Brass IS 319 Type (I) or BS 249 Type (I) or High Grade

⇒ Any Special Brass Material Composition as per customers requirement

⇒ Stainless Steel Turning Grades like 303, 304 etc.

⇒ Mild Steel Grades like EN 1A (BS 970 230M07) etc.

⇒ Aluminum Turning Grades like 1070 etc.

⇒ For connecting pipes or fittings of different types

⇒ Brass for corrosion resistance, ductility at high temperatures, and low magnetic permeability

⇒ Operating temperatures range from -53 to 121 degrees C (-65 to 250 degrees F)

⇒ Meets specifications ASTM B584 and ASME/ANSI B16 for quality assurance

⇒ ISO Metric (MM Threads)

⇒ British Standard Threads BSP,BSPT,BSW,BSF,BA

⇒ ASTM threads like NPT,NPTF, UNC, UNF

⇒ PG Threads

⇒ Edison Threads

⇒ Or almost any threads as per custom specification

⇒ Natural Clean

⇒ Nickel

⇒ Silver

⇒ Tin

⇒ White

⇒ Yellow or Blue Zinc